Pad Eye

Pad Eye

Grade: 316-NM Stainless Steel

Retail and bulk packaging available

The Pad Eye is offered in a variety of sizes from 3/16″ to 3/4″ and is ideal for marine, industrial, architectural, OEM and government applications. The working load limit is dependent on the quality of the welding and attachment structure. The underside is machined for a perfect seating.

Specifications

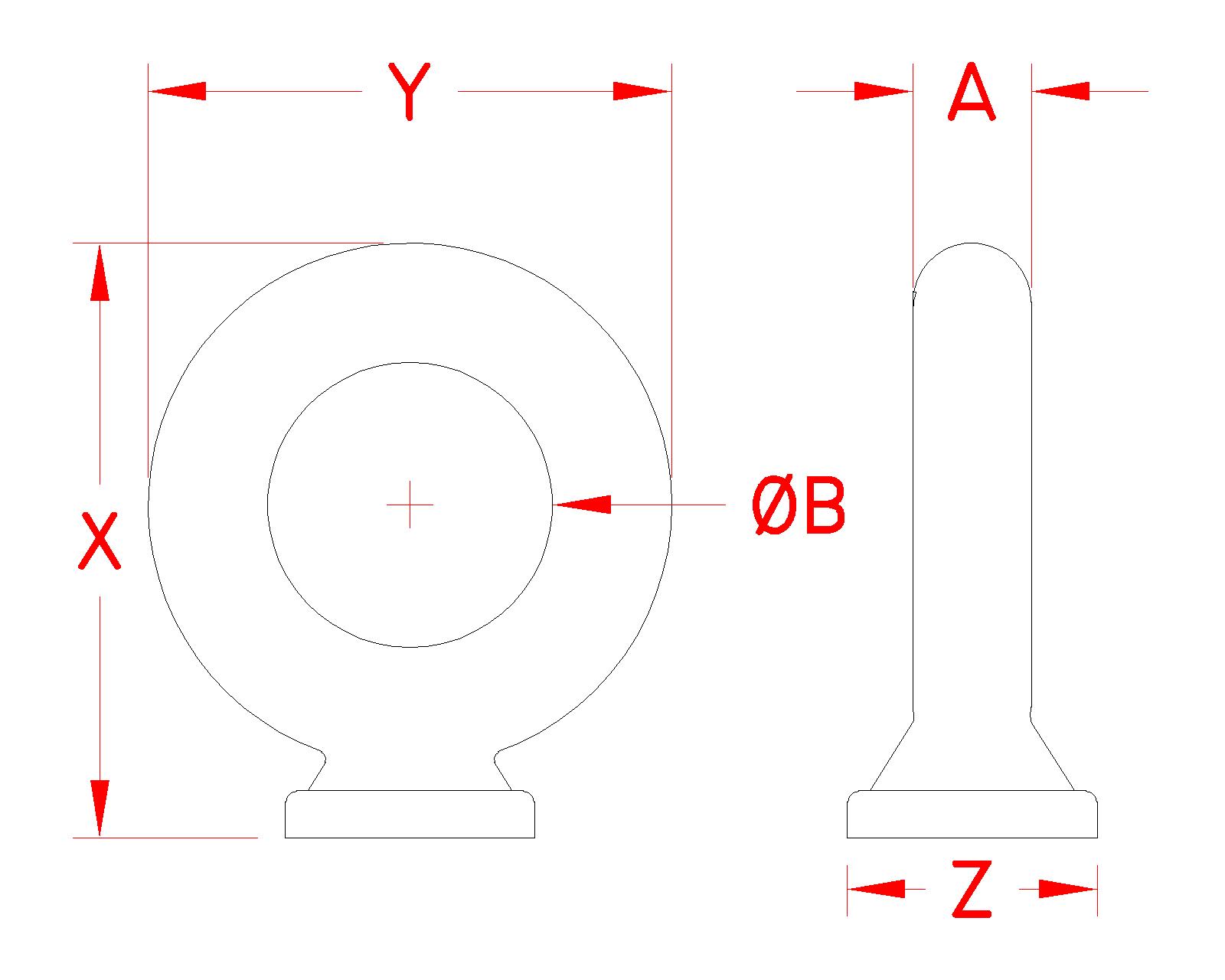

ALL DIMENSIONS ARE NOMINAL (+/- 3%) AND ARE SUBJECT TO CHANGE WITHOUT NOTICE.

| ITEM | A (size) | B | X | Y | Z | WT (lb) |

|---|---|---|---|---|---|---|

| S0324-0005 | 3/16″ | 0.50″ | 1.06″ | 0.90″ | 0.38″ | 0.03 |

| S0324-0007 | 1/4″ | 0.63″ | 1.31″ | 1.15″ | 0.56″ | 0.06 |

| S0324-0008 | 5/16″ | 0.75″ | 1.56″ | 1.40″ | 0.63″ | 0.10 |

| S0324-0010 | 3/8″ | 1.00″ | 2.00″ | 1.75″ | 0.87″ | 0.21 |

| S0324-0013 | 1/2″ | 1.25″ | 2.50″ | 2.25″ | 1.00″ | 0.38 |

| S0324-0016 | 5/8″ | 1.50″ | 3.25″ | 2.75″ | 1.38″ | 0.80 |

| S0324-0020 | 3/4″ | 1.75″ | 3.78″ | 3.25″ | 1.80″ | 1.46 |